Latching Solenoid Valves: Revolutionizing Fluid Control with Minimal Power Consumption

In the world of fluid control, innovation is key to driving efficiency, reducing energy consumption, and improving overall system performance. One such innovation that has been gaining significant traction across industries is the latching solenoid valve. These valves are transforming how industries approach fluid control by offering an intelligent solution that minimizes power consumption while maintaining high-performance standards. With applications ranging from industrial automation to automotive systems, latching solenoid valves are playing a pivotal role in creating more sustainable and cost-effective systems.

What is a Latching Solenoid Valve?

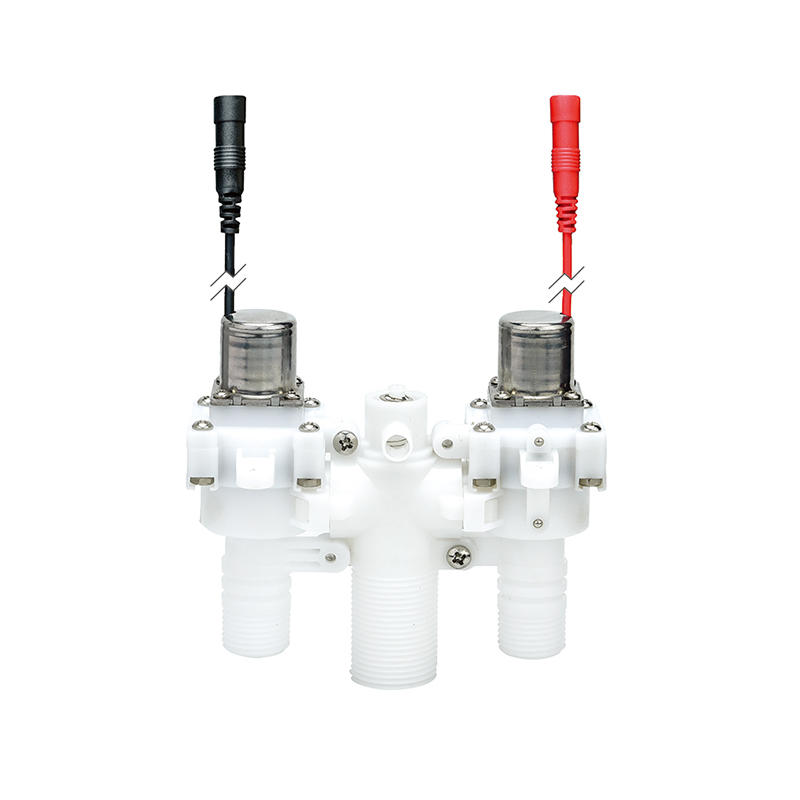

At its core, a latching solenoid valve is a type of solenoid valve that utilizes an electromechanical actuator to control the flow of liquids or gases within a system. What sets latching solenoid valves apart from traditional solenoid valves is their unique mechanism: they latch into position after being energized, requiring no continuous power to maintain their state. This drastically reduces the power required to operate the valve, making it an energy-efficient alternative for many applications.

In a traditional solenoid valve, power is required to hold the valve in either the open or closed position. This constant power consumption can be a significant source of inefficiency, particularly in systems where the valve remains in one position for extended periods. Latching solenoid valves, on the other hand, use a pulse of energy to shift the valve into the desired position, and then they remain there without requiring continuous power. This simple yet effective mechanism is what makes them particularly valuable for energy-conscious industries.

The Key Advantages of Latching Solenoid Valves

1. Reduced Power Consumption

The significant advantage of latching solenoid valves is their ability to drastically reduce power consumption. Since they do not require constant power to maintain their position, they can significantly lower energy costs in systems that rely on solenoid valves for operation. This is especially crucial in large-scale systems, such as industrial automation, where the cumulative energy savings can be substantial over time.

For instance, in water treatment plants or HVAC systems that employ numerous solenoid valves, the power savings associated with latching valves can to long-term cost reductions. As the world continues to focus on sustainability, energy efficiency is no longer just a competitive advantage; it has become a critical requirement for businesses looking to reduce their carbon footprint.

2. Enhanced Reliability and Durability

Latching solenoid valves offer enhanced durability compared to their conventional counterparts. Because they only draw power in short bursts to change position and then maintain that position without needing constant power, there is less wear and tear on the components of the valve. This leads to fewer instances of malfunction, extending the lifespan of the valve and reducing the need for frequent maintenance or replacement.

This increased reliability is essential in critical systems where downtime can result in significant losses. For example, in the automotive industry, where solenoid valves are used for fuel management, ensuring that the valves operate reliably can improve overall vehicle performance and fuel efficiency.

3. Increased Efficiency in Automation Systems

Latching solenoid valves play a critical role in the automation sector, where the need for efficient, low-power systems is more pressing than ever. These valves are commonly used in fluid handling, controlling processes such as filling, dispensing, and regulating the flow of liquids and gases in automated systems.

By reducing energy consumption while maintaining consistent performance, latching solenoid valves help to optimize the entire automation system. In packaging lines, for instance, valves are used to regulate the flow of liquids like oils, chemicals, or beverages. Latching solenoid valves allow for precise control without the energy overhead traditionally associated with solenoid valves, to higher efficiency and lower operating costs.

4. Versatility Across Applications

Another major benefit of latching solenoid valves is their versatility across a wide range of industries. Whether it's automotive, aerospace, medical, or even consumer appliances, latching solenoid valves are used in a variety of applications.

In the automotive industry, latching solenoid valves can be found in fuel management systems, airbag deployments, and exhaust gas recirculation. These applications benefit from the valve's ability to remain in the desired position without constant power, thus enhancing the overall efficiency and longevity of the vehicle’s systems.

English

English Español

Español